Are you looking for the very best custom metal fabrication and CNC metal forming services in Minnesota, Wisconsin or other areas like Iowa, Illinois, North Dakota, South Dakota and nationally? At Wyoming Machine, Inc., we’ve spent years expanding and fine-tuning our capabilities to ensure that we have the expertise, tools, systems and processes required to meet the exacting needs of a diverse range of industries.

Our sheet metal fabricators are experienced with a variety of materials including steel, stainless steel, aluminum and more. We utilize the latest CNC technology to produce high-precision parts and products with tight tolerances. Contact us today to learn about our custom metal fabrication services, or to begin your order!

Our Custom Metal Fabrication Equipment and Services

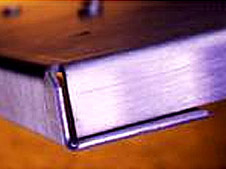

At Wyoming Machine, Inc., our technically skilled craftsmen and our state-of-the-art custom metal fabrication equipment perform precision forming that includes both brake and roll forming. To deliver the ultimate in quality and precision whether forming sheets or plates, our electric and hydraulic machines are CNC controlled, with a 6-axis back-gauge, multiple setups and tonnage up to 250 tons.

At Wyoming Machine, we’re a company that’s serious about quality and compliance. Our metal forming processes can meet tolerances of ±.010″ and ±.5°, in addition we’re also ISO 9001:2015 certified.

As part of our commitment to delivering added value to customers in sectors such as aerospace, defense and electronics, we offer extra services that are relevant to our core custom metal fabrication capabilities. Our design for manufacturability, engineering support, quick-turn prototyping, and grinding and hardware insertion are just a few of the special services that make sense for our specific customer base. For more information on our precision forming capabilities and value-added services, see the table below or contact us directly.

A Long History of Quality Services

Founded all the way back in 1974, Wyoming Machine Inc. is a woman-owned family business that takes pride in high levels of quality for any kind of custom metal fabrication need. Our sheet metal fabricators use the latest technology and equipment to ensure precision and efficiency in every project. We have over 45 years of experience serving industries such as aerospace, medical, defense, electronics, and more.

Our commitment to quality control has allowed us to become ISO 9001:2015 certified, showcasing our dedication to providing the highest level of customer satisfaction. Our team is highly trained and skilled in all aspects of metal fabrication, from design and engineering to welding and finishing. Contact us today to learn more!